Magnaflux

Magnaflux EV6000 LED UV Black Light

Share

-

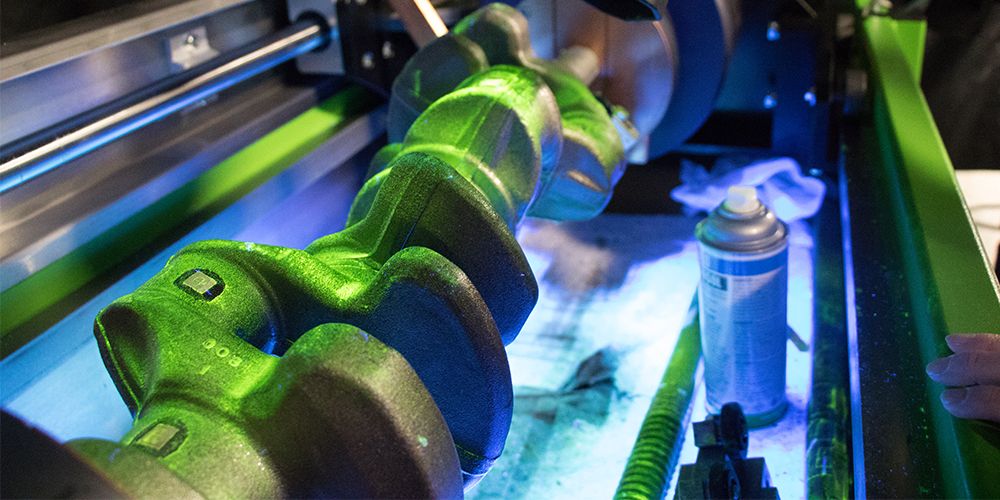

Magnetic Particle Inspection

Magnaflux Magnetic Particle Inspection (MPI) is a nondestructive testing (NDT) method that does not harm the parts being inspected. MPI is a cost-effective and reliable testing method commonly used to identify surface and slightly subsurface discontinuities in ferromagnetic materials. The process is used on machined parts, iron and steel castings, forgings, welds, parts that undergo heat treatment, and several other applications that will be placed into service or already are in service and require maintenance. MPI is often used to locate defects in mechanical parts in the aerospace, automotive, oil & gas, welding and power generation industries.

-

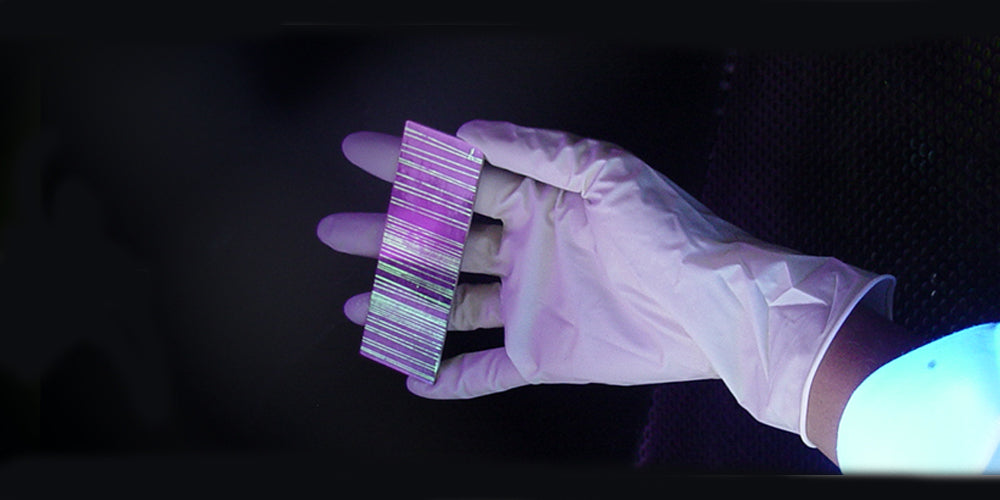

Pentrant Inspection

Magnaflux Liquid Penetrant Inspection (LPI) is a nondestructive test method which does not harm the parts being inspected. The testing methods detect cracks, fractures, laps, seams and other flaws that are open to the surface that may have been caused by fatigue, impact, quenching, machining, grinding, forging or overload. The process is used on machined parts, castings, forgings and other items that will be placed into service or already in service requiring maintenance.

-

Ultrasonic Couplants

NDT technicians trust Magnaflux to supply couplant for ultrasonic testing that enhance sound transmission from the transducer to the test part to produce reliable non-destructive inspection results in flaw detection, thickness gauging, flow metering and acoustic emission testing.

Find out more about why Magnaflux chose Sonotech couplants for a wide range of UT testing applications including high-temperature, shear wave, nuclear testing, power generation, aerospace inspections and many more.

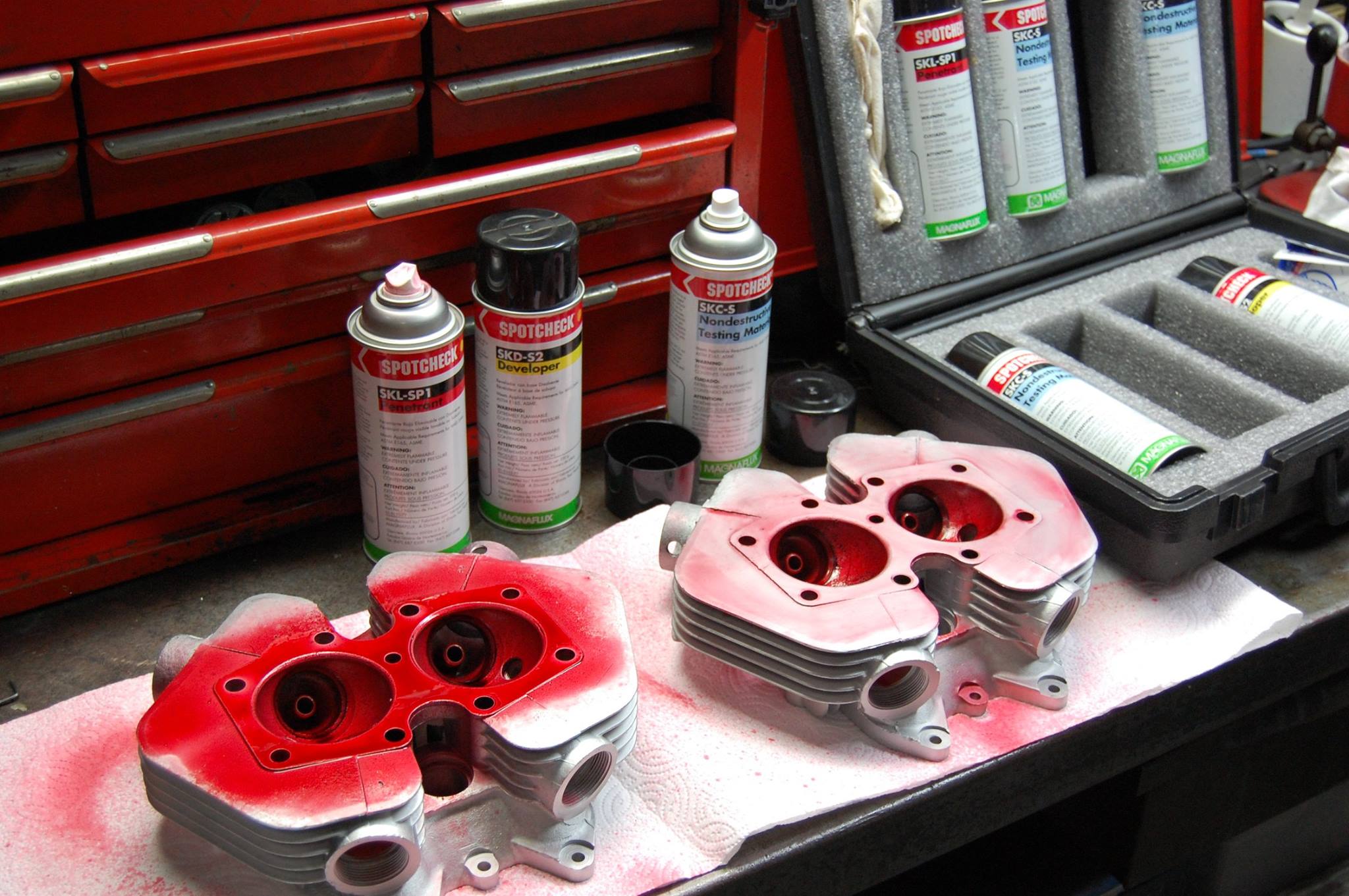

AEROSOLS ARE BACK

All aerosol products are in stock!

VISIBLE INSPECTION

Spotcheck Red Dye Penetrant